The pharmaceutical industry continues to grow exponentially, with demand for effective and innovative drugs at an all-time high. Dapagliflozin, a crucial medication for managing Type 2 diabetes, has garnered significant attention. Understanding the Dapagliflozin production cost is pivotal for stakeholders, including manufacturers, suppliers, and investors. This article delves into the nuances of the production cost, covering cost modeling, pre-feasibility studies, industrial trends, labor charges, utilities, logistics, and the supply chain.

Dapagliflozin Overview

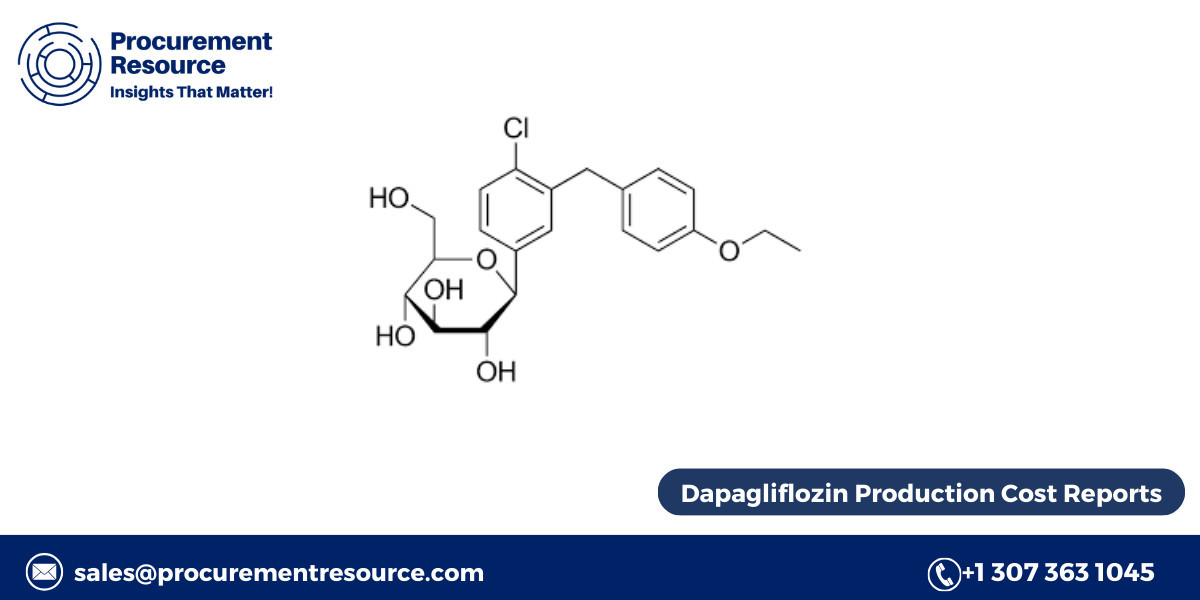

Dapagliflozin belongs to the class of medications known as sodium-glucose co-transporter 2 (SGLT2) inhibitors. It is primarily prescribed to manage blood sugar levels in adults with Type 2 diabetes. Additionally, it has shown efficacy in reducing the risk of cardiovascular complications and hospitalizations due to heart failure.

Given its widespread utility, optimizing the production process of dapagliflozin is a priority for pharmaceutical companies to ensure cost-effectiveness and profitability while maintaining high-quality standards.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/dapagliflozin/request-sample

Cost Model for Dapagliflozin Production

Developing a robust cost model is essential for estimating and managing the Dapagliflozin production cost. Here are the primary components of the cost model:

Raw Material Costs:

The synthesis of dapagliflozin involves advanced intermediates and reagents. The cost and availability of these raw materials can significantly impact the overall production expense.

Bulk procurement of raw materials can reduce costs through economies of scale.

Process Efficiency:

Utilizing advanced production techniques and optimizing reaction conditions can minimize waste and improve yields, thereby lowering costs.

Innovations in green chemistry and continuous manufacturing processes are gaining traction.

Fixed and Variable Costs:

Fixed costs include expenses like equipment purchase, plant setup, and depreciation.

Variable costs encompass electricity, solvents, catalysts, and other consumables.

Quality Assurance:

Compliance with regulatory standards requires stringent quality control measures, adding to the production cost.

Pre-Feasibility Studies

Conducting a pre-feasibility study is a crucial step before initiating dapagliflozin production. This involves:

Market Analysis: Evaluating demand trends, target demographics, and competitive landscape.

Site Selection: Choosing a location with easy access to raw materials, utilities, and skilled labor.

Cost Assessment: Estimating initial capital investment, operational costs, and potential revenue.

Risk Evaluation: Identifying potential challenges such as supply chain disruptions or regulatory hurdles.

Industrial Trends Impacting Dapagliflozin Production

Sustainability:

The industry is increasingly focusing on eco-friendly production practices, including waste minimization and reduced carbon emissions.

Automation:

Automated systems and AI-driven analytics are being integrated into production lines to enhance efficiency and reduce human errors.

Globalization of Supply Chains:

While globalization offers cost advantages, it also exposes manufacturers to geopolitical risks and supply chain disruptions.

Regulatory Frameworks:

Compliance with stringent regulatory standards like cGMP (current Good Manufacturing Practices) and ISO certifications is non-negotiable for pharmaceutical manufacturers.

Labor Charges and Utilities

Labor and utility expenses form a significant portion of the Dapagliflozin production cost.

Labor Charges:

Skilled labor is essential for carrying out precise chemical reactions, maintaining equipment, and ensuring product quality.

Labor costs vary depending on the production facility’s location, with lower costs in developing countries but higher wages in developed economies.

Utilities:

Energy consumption is a major utility cost, especially for processes requiring high temperatures or pressures.

Water, cooling systems, and waste treatment facilities also contribute to the utility expenses.

Logistics and Supply Chain Management

Efficient logistics and supply chain management are critical to minimizing production costs and ensuring a steady supply of dapagliflozin to the market.

Raw Material Procurement: Partnering with reliable suppliers to ensure the availability of high-quality raw materials at competitive prices.

Inventory Management: Using just-in-time (JIT) strategies to reduce holding costs and avoid overstocking.

Transportation: Optimizing shipping routes and modes to reduce transit times and costs.

Risk Mitigation: Implementing contingency plans to address potential supply chain disruptions, such as geopolitical tensions or natural disasters.

Procurement Resource for Dapagliflozin Production

Organizations like Procurement Resource play a vital role in providing in-depth cost analysis and market insights for dapagliflozin production. Their comprehensive reports encompass:

Detailed cost models and feasibility studies.

Market dynamics and price trends.

Supplier analysis and benchmarking.

Strategic recommendations for cost optimization.

Request a Free Sample

Get access to a detailed Dapagliflozin production cost report that provides invaluable insights into cost modeling, industrial trends, and supply chain management. This report is a must-have resource for pharmaceutical companies, suppliers, and investors looking to understand and optimize production costs.

Click here to request a free sample of the Dapagliflozin Production Cost Report: https://www.procurementresource.com/production-cost-report-store/dapagliflozin/request-sample

Understanding the Dapagliflozin production cost is essential for pharmaceutical manufacturers aiming to remain competitive in a rapidly evolving market. By leveraging comprehensive cost models, conducting pre-feasibility studies, and staying abreast of industrial trends, companies can streamline their operations and enhance profitability. Efficient labor management, utility optimization, and robust supply chain strategies further contribute to cost-effectiveness.

With detailed insights and support from industry experts like Procurement Resource, stakeholders can navigate the complexities of dapagliflozin production and ensure sustained growth in this dynamic sector.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA